Oil & Gas Inspection

Services

Oil & Gas Inspection

About

is an analytical tool focused on preventing releases of any substance defined as a "highly hazardous chemical" by the EPA(Environmental protection act)or OSHA. Process Safety Management (PSMS) refers to a set of interrelated approaches to managing hazards associated with the process industries and is intended to reduce the frequency and severity of incidents resulting from releases of chemicals and other energy sources (US OSHA 1999). These standards are composed of organizational and operational procedures, design guidance, audit programs, and a host of other methods.

About

Level 1

Level 1 assessments require the least amount of data and experience. This type of assessment usually uses tables and screening curves and requires few computations. This means the computations can be quite conservative, similar to design code calculations. This level of inspection tends to take less time than the other two.

Level 2

If a Level 1 assessment on a piece of equipment does not meet acceptance criteria, a Level 2 assessment can be performed. A Level 2 assessment requires significantly more involved computations to replace the simple, conservative computations that make up the Level 1 assessment. The benefit is that fewer conservative calculations may lead to a better outcome, but the computations are complex enough that FFS software is often required.

Level 3

Generally, Level 2 assessment criteria are met and the equipment can be returned to service. But, In severe cases, a Level 3 assessment may be required. Compared to the previous two levels, a Level 3 assessment requires more detailed data and a considerable amount of operational experience on the part of the inspector. Because of errors that can occur due to using the more advanced equipment Level 3 analysis are rarely conducted.

The factors that go into selecting a level of FFS include the quantity of data available with which to perform an evaluation, the quality of that data, and the degree of significance of the analysis to equipment operations.

Posts

Inspection

we are specialist

•Fitness For Service Calculation

For Piping / Tanks / Pressure vessel

Single Video

Reports pdf

Who are we?

Inspection Procedures for different types of equipment According to API Inspection Codes for in-service Equipment (Tank/Pressure Vessel/Piping). These include the evaluation and rerating If required.

we have 20 years’ experience in-service inspection (during operation) and shutdown in oil & gas refineries.

API Certified in : 510 pressure vessel & 570 piping

Duties and Responsibilities:

Working with API 570/510/653/580/579/ASME code

API Certified in : 510 pressure vessel & 570 piping

Duties and Responsibilities:

Working with API 570/510/653/580/579/ASME code

- In service inspection and evaluation by fitness for service /Risk assessment / Risk Ranking

- Inspection calculation (corrosion Rate/ remaining life/ next inspection date)

- Review Design Data according to ASME Codes.

- Calculation for :(required thickness / MAWP)

- Review inspection reports according to API inspection codes.

- Prepare Inspection plan / inspection procedures

- Prepare & Develop checklist for internal and external inspection for the plant equipments

- Give advice for on-stream inspection with advanced techniques

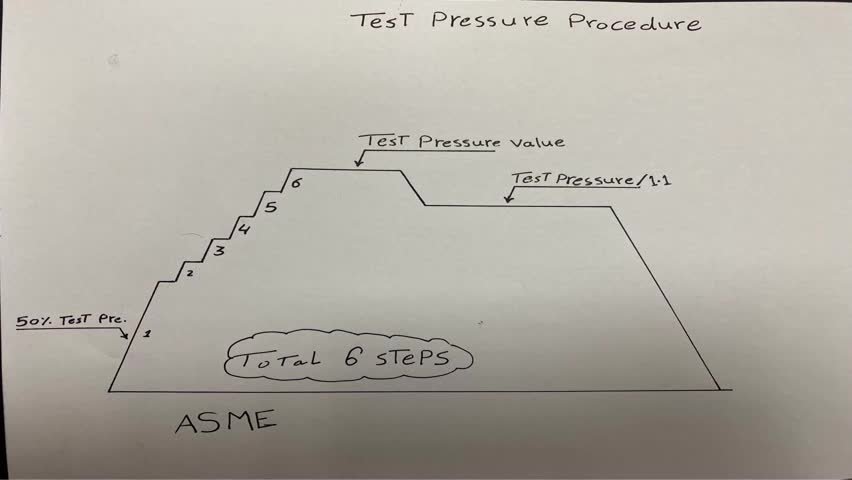

- Prepare hydrotest and pneumatic test procedures for tanks, pressure vessel, piping

- Prepare inspection reports (activity, analysis, recommendation, fitness for service).

- Advising, guiding and motivating line management on all QA/QC activities and related technical matters.

- Prepare & Develop work procedures & instructions for preventive / predictive maintenance for the plant equipments.

- Assist & Participate in the selecting & evaluation of vendors / contractors assigned for maintenance activities.